The Story of Quattro

The Story of Quattro: Fortune & Fate From Four Vineyards

Quattro represents the harmonious result of a winemaker’s instinct, quick thinking, and a touch of serendipity. It all began on October 15 during the 2012 harvest, there remained a small quantity of grapes from 4 outstanding Napa Valley Cabernet vineyards, and it looked as though the fermentation vessels were already full. With limited tank space remaining, Winemaker Peter Velleno found himself in a jam. Recognizing the exceptional quality of the fruit, he made a bold decision – to ferment these precious remnants together in a single small tank.

When the time was right, just as the fermentation was nearing its completion, the winemakers gathered to taste the wine. In that moment, it became evident that an ideal blend had taken place. This prompted them to christen it “Quattro,” in honor of its origins from the 4 distinct vineyard sites across the Napa Valley.

Ever since that fateful day, no further blending has been done with this wine, preserving its unique and authentic character that arose from the different vineyards. Quattro remains a testament to the artistry of winemaking and the importance of nature’s elements. Discover the bold character and rich complexity of the 2019 Quattro Napa Valley Cabernet Sauvignon, now available in our online shop.

The vineyards last utilized for this unique Cabernet are Gerlach Hammond, Perata, Rocca, and Villa Amorosa; vineyards typically used in the final blends of our Barone Cabernet Sauvignon and La Castellana Super Tuscan Blend. Quattro’s powerful, structured tannins are backed by hints of blackberry, cassis and leather. This bold Cabernet Sauvignon pairs perfectly with filet mignon.

Past Awards & Accolades

Explore our past awards and accolades for our Quattro, Cabernet Sauvignon.

♦ 94 Points – American Fine Wine Competition 2021- Gold Medal

“More than 550 wines from 125 wineries vied for top honors at this invitation only event. The Judging was conducted by a 28-member blue ribbon panel from across the wine industry, included educators, restaurateurs, retailers, journalists, and top sommeliers from across the country.”

♦ 93 Points – Owen Bargreen

“The outstanding, deeply-colored 2018 Castello di Amorosa ‘Quattro’ Cabernet Sauvignon spent 20 months in 65% new French oak before bottling. Ripe dark currants and huckleberries mark the nose, alongside wet gravel and graphite notes. The palate is soft and very seamless, creating a weightless effect. Drink 2022-2034.”

Solar at The Castle

Solar at The Castle

We invested $1.4 million in a 450-kilowatt solar power array. The massive 1162 panel system was completed in January of 2022 and is situated on a spot which had been a forested slope but was significantly burned in the Glass Fire that hit the Napa Valley in 2020.

“This enormous investment is an important element of our commitment to become as self-sufficient as possible while minimizing our carbon footprint and helping with the climate change crisis. We expect this will offset our energy usage around 80%,” explains Georg Salzner, President, Castello di Amorosa.

Castello di Amorosa partnered with Centrica, Recolte Energy, 127 Energy and DEIF on the multiple components of this installation. 127 Energy designed the 556-kilowatt battery storage microgrid. Using advanced and remotely accessed power controls, the solar microgrid provides Castello di Amorosa with an independent power supply during frequent utility grid outages. During times of normal operations, the solar microgrid reduces utility energy charges and demand charges, resulting in significant operational savings for the winery.

“Due to fire risks and skyrocketing power prices, commercial business owners in California are taking matters into their own hands. Castello di Amorosa, Centrica Business Solutions, and Sungrow were great partners on this project and our collaboration exemplifies how innovative teams can solve daunting environmental and energy-related challenges,” said Mark Crowdis, CEO of 127 Energy. “The battery storage microgrid provides a striking juxtaposition of resilient, clean energy technology against the backdrop of historic castle grounds,” Crowdis added.

Other examples of Castello di Amorosa’s environmentally friendly programs and practices:

· Napa Green Certified: the winery has been Napa Green Certified since May 2018 (renewed in June 2021). Being Napa Green Certified’s requirements include LED Lighting, using a minimum of 50% recycled paper in the winery offices; using recycled cardboard and recycled pulp for shipping (instead of Styrofoam), using green certified cleaning agents and hand soap; using recyclable/compostable plates/flatware.

Bio Microbics Micro Fiber filtration system: the winery treats all of its processed water (water used during production of wine) and re-uses it for landscaping. Since 2017, the winery has treated and re-used over 5,000,000 gallons of water.

· The winery has begun composting as of January, 2022.

· Napa Ride Share program: the winery pays employees to carpool, thus eliminating more cars on the road.

Castello di Amorosa owns and farms 130 acres in Napa, Sonoma and Anderson Valley.

Night Harvest at the Castello

Night Harvest at the Castello

Castello di Amorosa sits in the hillsides of the Diamond Mountain District of Napa Valley, and is surrounded by 30 acres of vineyards planted to Cabernet Sauvignon, Sangiovese, Primitivo, and Merlot. These medium-to-full-bodied wine grapes are typically picked in the later half of the harvest season, and this year we are right on schedule with the start of the estate harvest, as this past Wednesday night we harvested our Block 5 Merlot. The first block of fruit to be harvested at the Castello this year, it sits along the entryway to the Castello, along the left hand side of our driveway as you come up the hill.

Harvesting fruit at night is an excellent way to preserve the acidity of the berries and ensure that they arrive on the crush pad in optimal condition. The berries are also much firmer at these temperatures, making it easier to sort and destem clusters on the crush pad.

Night harvesting also provides better working conditions for the vineyard teams who work tirelessly to hand pick each cluster, ensuring only the best reach the winery. Crews will often make several passes through the same vineyard over a period of days or weeks to ensure that each cluster reaches peak ripeness before being picked.

If you’re visiting Napa Valley this time of year, be sure to keep an eye out for bright lights in the vineyards after dark; these are signs of hardworking vineyard crews harvesting the beautiful fruit of the 2018 vintage.

Concrete Egg Fermentation

Concrete Egg Wine Fermentation Tanks

If you have been lucky enough to explore our Grand Barrel Room on a tour and tasting recently at the Castello, you may have noticed a few new additions to the stunning 12,000 square foot room. Right next to where our guests have the chance to taste wine straight from the barrel, there sit several large, concrete, egg-shaped containers. These concrete eggs are wine fermentation tanks, and they are used to ferment a special selection of Castello’s award-winning wines.

Concrete? You might ask. What can concrete do for wine? Well as it turns out, concrete is a fantastic alternative to oak or stainless steel in winemaking. Without the “oaky” impact on a wine from barrel aging, the concrete allows the wine to retain its fruity characteristics and the inherent characteristics of the grapes are allowed to shine, making it an especially useful fermentation method for showcasing the terroir of single vineyard wines.

Concrete eggs are an interesting mix of ancient and ultra-modern winemaking techniques, since the first wines were actually fermented in pottery jars called amphorae. The egg shape is a newer modification, which allows the wines inside to have a natural convection current as the carbon dioxide released during fermentation helps to naturally stir the wine and mix in the sediment, or lees.

“Graeco-Italic” Wine Amphora, 2nd century B.C.

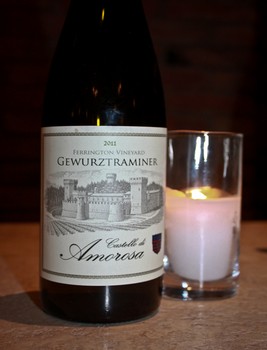

We originally had two concrete eggs in our Grand Barrel Room, and focused on several single vineyard wines, including our Ferrington Vineyard Dry Gewürztraminer and Tyla’s Point Pinot Bianco. These aromatic varietals work especially well with this fermentation method, because the concrete enhances the floral aromas and even increases the mineral characteristics in these wines. The elegant complexity of these wines from their fermentation in the eggs has led to them both winning high praise from tasting panels and our guests.

Our 2011 Ferrington Dry Gewurztraminer

This past year we have also produced a limited amount of Chardonnay, called “La Rocca” or “the fortress.” Our Winemaker, Peter Velleno, explains that “the reason for the Chardonnay is that the use of concrete (or more specifically the lack of oak barrels) allows the flavor of the vineyard to be the star. Chardonnay needs to have a rich mouthfeel, so it makes sense to try it in concrete, where there will be no oak flavors or aroma, but still the benefits of aging on the lees.” Aging wine on the lees, or the yeast and sediment that settles to the bottom of the barrel during fermentation, imparts a creaminess and complexity that can’t be found in stainless steel. This year we are excited to be fermenting some of the Chardonnay fruit from the Bien Nacido vineyard in one of our eggs.

So keep an eye out the next time you visit the Castello, and if you take a tour down into the Grand Barrel Room you’ll be able to check out this unique fermentation technique that helps to make our Italian-style wines even more incredible!

Red Wine Barrel Fermentation

How to Ferment Wine: Our Red Wine Oak Barrel Fermentation Process

During the Harvest season, there are always exciting things going on around the Castello, and today on the Crush Pad was no exception. Today, for the first time at the Castello, our winemaking team reserved a small lot of our Don Thomas Vineyard Cabernet Sauvignon for fermentation directly in French Oak Barrels.

Traditionally, the fermentation process takes place in stainless steel tanks, where the must (skins and seeds of the grapes) are cold-soaked with the juice before yeast is added. The cap, or layer of skins and seeds that get pushed to the top of the tanks from the activity taking place during fermentation, is broken up by either the punch-down or pump-over method, both of which ensure an even distribution of the color and flavors we wish to impart into our red wines. After five to eight days in these fermentation tanks, the juice is pressed from the skins and seeds and pumped into French Oak barrels for aging in the Castello’s extensive underground cave and cellar system.

What is barrel fermentation? Barrel fermentation means that the freshly destemmed grapes and their juices are pumped directly into French Oak barrels whose heads have been removed. Dry ice is added to cool the berries before the barrel heads are secured to seal in the must. The barrels are then laid on a rack that allows them to be rolled back and forth daily to ensure the cap stays moist and the oak is evenly introduced to the fermenting must and juice. Typically, two full barrels of must and juice will amount to one barrel of wine. The process of fermenting the juice in oak barrels helps to impart an added silkiness to the tannins and a rounder, more lush mouthfeel, especially to Bordeaux varietals. This extremely labor-intensive method of fermentation is typically reserved for only the most exclusive of wines, and the highly-acclaimed Cabernet Sauvignon from the Don Thomas Vineyard is an exceptional example of the quality of grapes deserving of such treatment.

The Don Thomas Cabernet Sauvinon clusters are conveyed into the berry sorter/ destemmer as a lucky tour group watches

The new French Oak barrels are filled directly from the destemmer

Our Cellar Supervisor, Chema, overseeing the juice and must being pumped into a special French Oak barrel that has a door in place to make filling and emptying easier

The deconstructed barrel waiting to be resealed with the juice and must inside

Dry ice is added to the must before the barrels are resealed to help cool off the berries

Resealing the barrel heads before they are sent into the cellars to begin the fermentation process

The barrels are stored in a special temperature-controlled room in the Castello’s cellars during the fermentation process.